Engineering Design Process

What Is It?

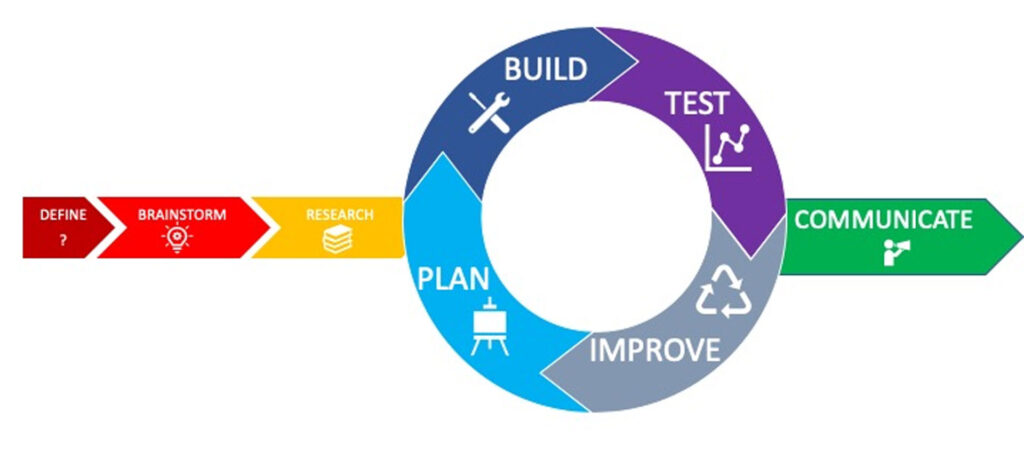

The engineering design process (EDP) is a series of steps that guides solving real-world problems. The EDP consists of the following steps: 1)Define the problem, 2) Brainstorm potential solutions, 3) Research solutions, 4) Plan, 5) Build, 6) Test, 7) Improve Solutions, and 8) Communicate results.

The design process is iterative, meaning that we repeat the steps as many times as needed, making improvements along the way as we learn from failure and uncover new design possibilities to arrive at great solutions.

Why Use the Engineering Design Process in CNC Machining?

The engineering design process is important for multiple professions and industries that use CNC and subtractive manufacturing. The EDP helps ensure that the CNC created object meets the desired specifications of the item or object needed to be fabricated. The engineering design process also can help identify potential design flaws and allows for testing of the CNC designed object to ensure that it meets the desired requirements, or provide new research and use cases for CNC machining. Additionally, the engineering design process helps to optimize the CNC machining process, which can help improve efficiency and reduce costs for industries or businesses.