3D Printing: Slicing Settings

The Slicing stage is the point where you will select many settings for your 3D print. Below you will find some common settings and what they

This setting determines the thickness of each layer that the 3D printer will print. Smaller layer heights result in smoother and more detailed prints but can increase print time. Larger layer heights are faster but may result in a less detailed and rougher finish.

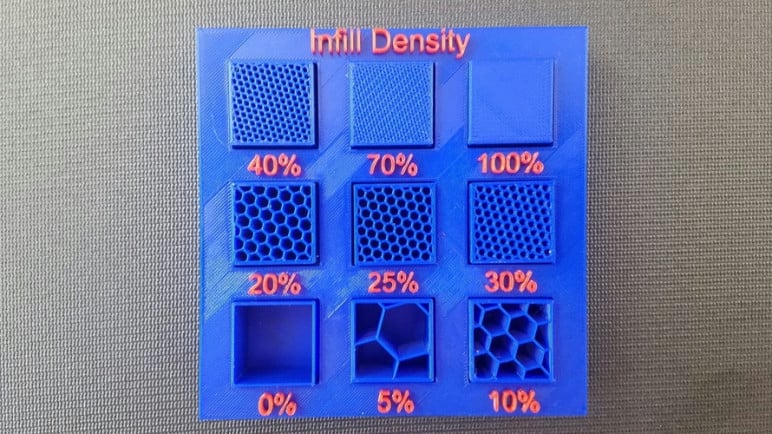

Infill refers to the internal structure of the printed object. This setting determines the percentage of material filled inside the object. Higher infill density provides more strength and durability but takes more time and material to print.

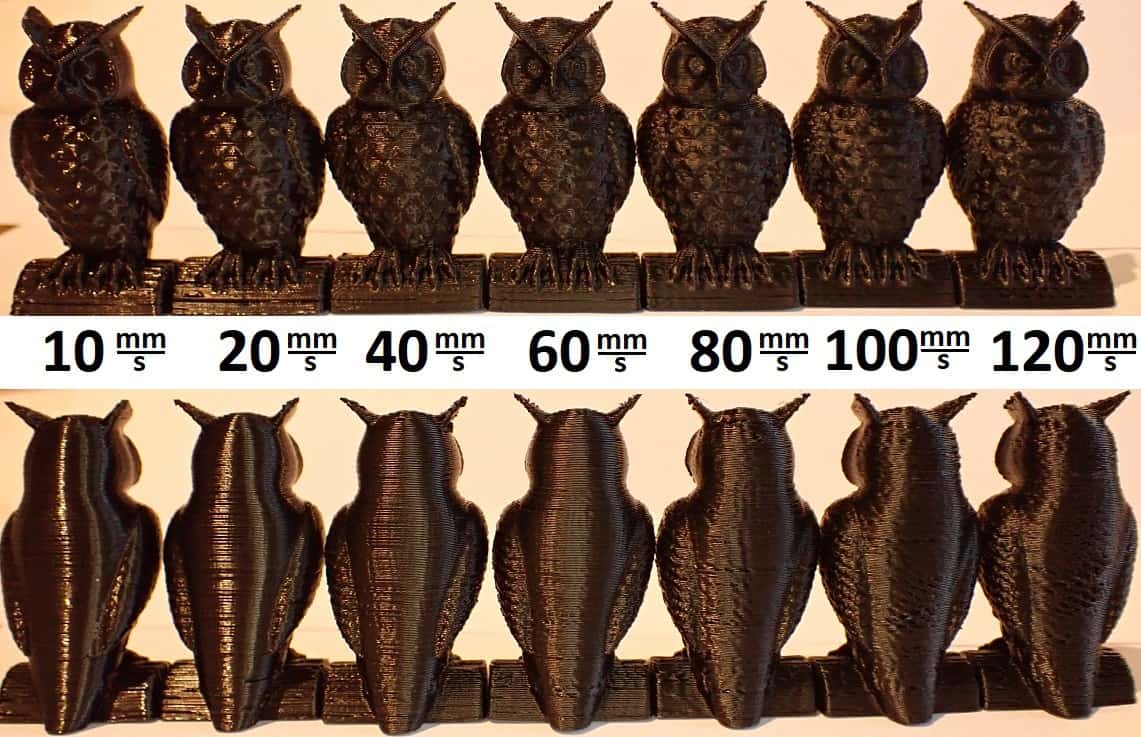

The print speed setting controls how quickly the printer’s nozzle moves while printing. Faster print speeds can reduce printing time, but it may compromise print quality, especially with complex or intricate designs. Slower print speeds usually produce better results, especially for detailed parts.

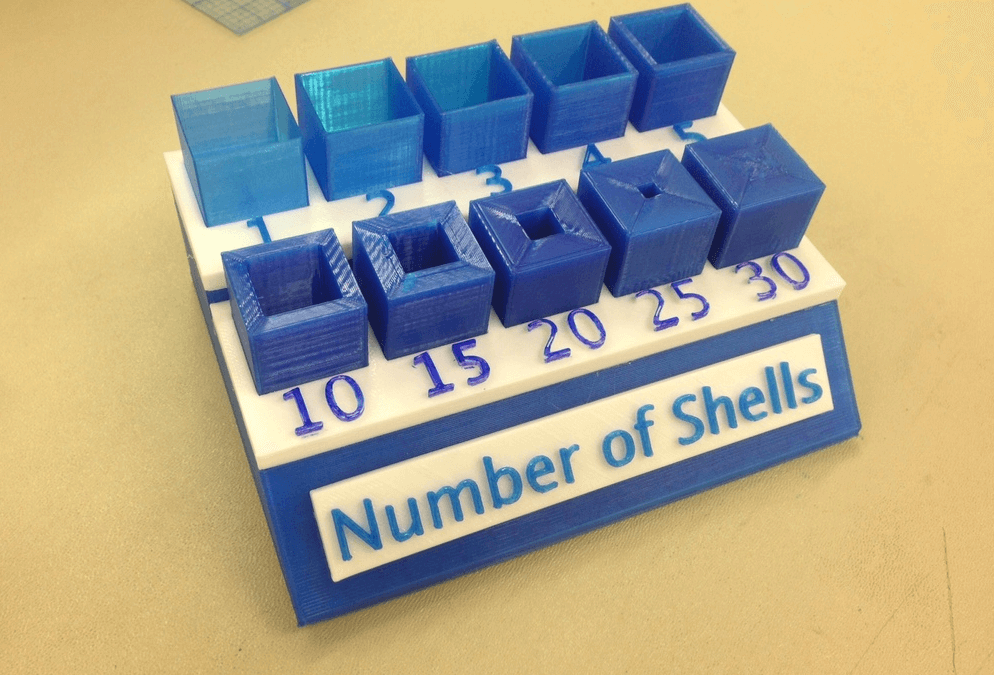

This setting controls the number of outer shells or perimeters for each layer of the print. Increasing the wall thickness can make the object more robust and solid, but it will also increase printing time.

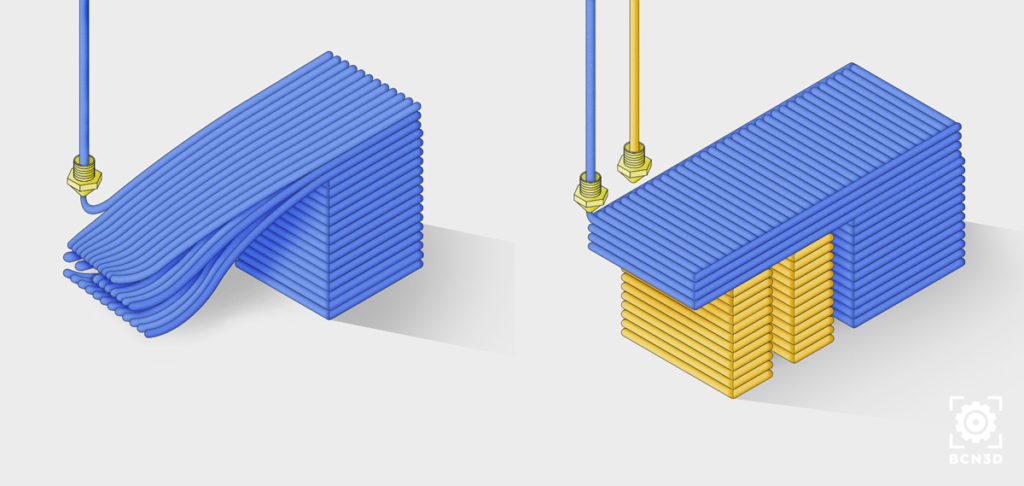

If your model has overhangs or bridges, support structures may be necessary to prevent sagging and improve print quality. Most slicer software can be automatically generate support, but some allow you to also add it manually.

Supports need to be removed carefully after printing. If the settings were correct, supports should be easy to remove by hand or with a simple tool. After removing supports you may want to sand your print to remove any burrs left by the supports.

Because of the extra processing and material required for supports, it is usually better to try and orient your print so that supports are not required.

A raft or brim is a thin layer of material printed at the bottom of the model to improve bed adhesion. Rafts create a separate layer between the model and the print bed, while a brim extends the outline of the model for better stability. Rafts and brims provide a larger surface area for the initial layers of the print to adhere to the print bed. This helps prevent warping and ensures better adhesion, especially for prints with a small contact area to the bed. By providing a stable foundation, the chances of print failures due to detachment from the bed are reduced.